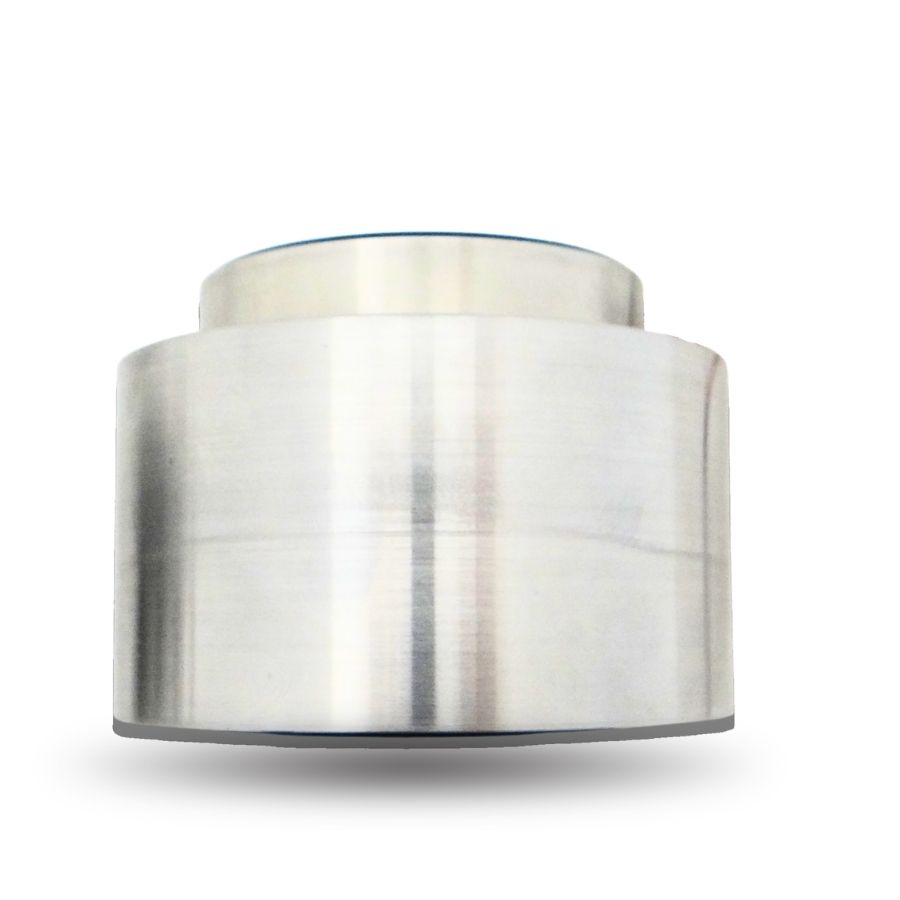

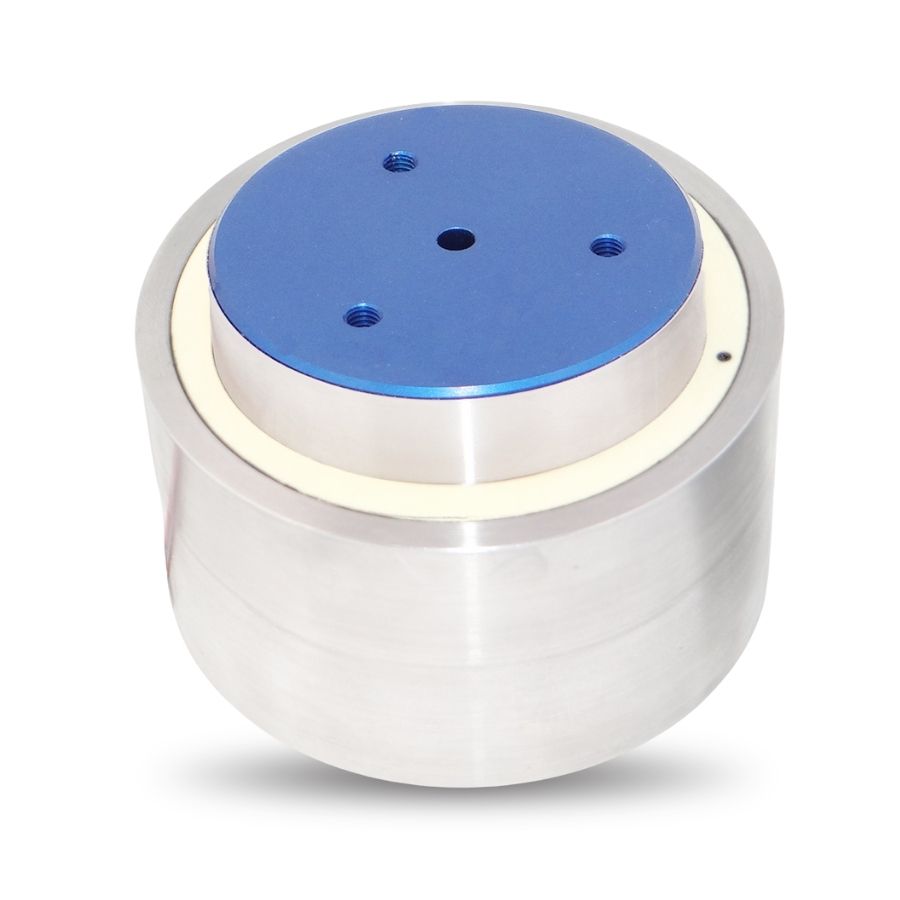

Magnetic Gravity Compensator Series

High-performance, contactless solutions for gravity compensation in precision mechatronic systems: based on anti-gravity magnet technology and magnetic force balancing. The Magnetic Gravity Compensator Series (MGC) delivers a stable, passive upward force — allowing your vertical motion systems to be more compatible while eliminating power dissipation for the vertical force component. It enables your systems to move faster, smoother, and with far greater control.

Used in robotics, semiconductor, and vacuum-based applications, the MGC reduces mechanical stress, eliminates static coil power loss, and enables low-stiffness positioning with high reliability.

Contactless

force delivery

No static

energy loss

No moving

wires

Supports 6-DOF

control

What is Gravity Compensation?

In many high-precision machines — like robotic arms, semiconductor stages, or inspection platforms — one often utilizes a part that moves vertically. However gravity constantly pulls it down.

This means your motors or actuators are always working, even just to hold the part still. That leads to:

- Unnecessary energy consumption.

- Heat generation that cause unwanted thermal expansion and distortion.

- Lager size connection wires.

- Wear and tear on components.

- Unwanted stiffness that reduces responsiveness and leads to extra position errors.

- Gravity-induced sagging.

- Adding on fail safes, for when the vertical actuator shuts down.

To make your system more efficient, stable, and accurate, you want the moving part to feel weightless. That’s exactly what gravity compensation does.

Gravity compensation is a technique used to neutralize the weight of a moving object — particularly in vertical motion systems.

Why not use springs or traditional actuators?

Traditional solutions like springs or preload structures introduce limitations — such as friction, mechanical wear, and nonlinear behaviour, drawbacks per method are:

| Method | Drawbacks |

| Springs | Add mechanical stiffness, can’t be tuned precisely, degrade over time |

| Coil/Motor force | Consumes energy even when idle, generates heat, connection wires, |

| Pneumatics | Bulky, noisy, not vacuum-compatible, piston friction and hysteresis |

| Active maglev | Complex, expensive, sometimes unstable |

How can our Magnetic Gravity Compensator Series help?

If you have a vertical moving part that needs to feel weightless — so it can move fast and accurately, without wasting energy, generating heat, or adding stiffness, our MSG Series can help.

The MGC series achieves this by creating a passive magnetic force that exactly balances the weight of the moving part. The result: your system performs like it’s floating on air, with minimal effort.

The technique behind the MGC Series

The MGC Series uses a combination of permanent magnets and optional lorentz coils to generate two separate forces:

Passive Bias Force (Anti-Gravity Magnet Force)

- Two magnetic assemblies generate a continuous force with extremely low parasitic stiffness in DOF6.

- This contactless magnetic field creates a constant upward force, exactly tuned by design to compensate for the weight of the moving mass.

- This eliminates direct mechanical couplings and prevents vibration transmission.

- This force requires no electrical power and introduces minimal stiffness as the coil portion is situated in the static part.

Active Z-Control Force (Only in A-models)

- A Lorentz coil provides a precise control force in the vertical direction which is added to the passive bias force.

- This enables a fast and dynamic response to external disturbances.

- Without adding heat or stiffness to the moving part.

Optimized design

- The coils and static magnet assembly form an efficient thermal path. This is beneficial for high force density.

- No moving wires = ultra-high reliability

- Durable, no mechanical wear points

- Optional water cooling can be used for additional heat dissipation.

- Both Bias Force and Lorentz Force work on the same part.

This gives you stable support and precision motion in a compact, reliable form. Without the complexity of full active levitation systems.

What makes the MGC Unique?

Unlike conventional actuators or magnetic bearings, the MGC separates gravity compensation from dynamic force control. As mentioned above: a passive bias force is created using dual magnet assemblies to balance weight without power or heat. A separate Lorentz coil then adds any required Z-axis actuation.

Key advantages include:

- Contactless operation with low stiffness

- Energy-efficient: no coil current required to counteract gravity

- No thermal load on the moving part

- Reliable in any orientation, Z and radial axis force support

- Zero energy loss in static operation

- Low parasitic stiffness (30–6000 N/m depending on model)

- Vacuum-compatible design options available.

- Suitable for 6-DOF applications: The radial clearance allows for controlled movements in six degrees of freedom, ideal for complex mechatronic applications.

MGC Series Technical Models Overview

From compact 40 mm diameter modules to 160 mm high-force versions, the MGC series covers applications from 6 N bias force up to 800 N.

Notes:

- The specifications are preliminary values. No rights can be derived from this specification.

- Custom designs, cooling options, and integration support are available on request.

- A-models include Lorentz Z-actuation / P-models provide passive gravity compensation only.

| Specification | MGC-A4025 | MGC-P6040 | MGC-A6550 | MGC-A16095 |

|---|---|---|---|---|

| Outer Diameter [mm] | 40 | 60 | 65 | 160 |

| Height [mm] | 25 | 40 | 50 | 90 |

| Vertical Stroke [mm] | 3 | 3 | 3 | 4 |

| Radial Stroke [mm] | 1.2 | 3 | 2 | 2 |

| Bias Force (F-Bias) [N] | 6 | 30 | 75 | 800 |

| Continuous Force [N] | 1.5 | – | 15 | 100 |

| Peak Force [N] | 4 | – | 40 | 400 |

| Max Stiffness Cz,x,y [N/m] | 30 | 175 | 600 | 6000 |

| Moving Mass [kg] | 0.024 | 0.040 | 0.115 | 2.85 |

1 Standard range at 22°C. Other dimensions and force ranges available upon request / 2 Continuous force at 25°C ambient and 155 °C coil temperature, depending on thermal path / 3 Peak force for 10 sec. at 25°C ambient and 155 °C coil temperature

For what industries is Gravity Compensation interesting and why?

The MGC is ideal for industries where gravity force disturbance degrades precision or speed, such as:

- Equipment – ultra-precise wafer stages, inspection modules

- Robotics – vertical axis compensation, high-speed pick-and-place systems

- Optical systems – vibration-sensitive lens and sensor platforms

- Vacuum environments – cleanroom and UHV-compatible setups

- Metrology & test benches – minimizing force cross-talk and error sources

- Magnetic levitation prototypes – passive support without levitation instabilities

Its low contactless stiffness and no moving wires design make it perfect for environments where both reliability and performance matter.

Get in contact with

the support team

If you would like to receive a quotation, have a question about our products, or want to know what we can do for you specifically. You can fill in our contact form. We will get back to you within 24 hours.